LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1 Powered by:300.cn

ABOUT US

Product center

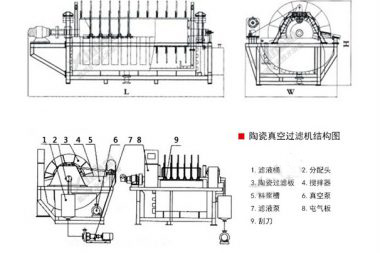

Ceramic filter

Product name:

Ceramic filter

浏览量 :

所属分类:

Dewatering equipment

Description:

A filter that relies on microporous ceramics for vacuum dewatering.

Application range:

Widely used in mining non-ferrous metals, rare metals, ferrous metals, non-metallic concentrates and tailings dehydration, chemical industry oxides, electrolytic slag, leach residue, slag dewatering and environmentally friendly sewage sludge waste acid tr

Applicable material:

Material fineness from -200 to -450 mesh and various ultra-fine materials

我要询价

Advantage

Principle

Parameters

Case

上一篇

Dewatering screen

下一篇

Plate and frame filter press