LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1 Powered by:300.cn

ABOUT US

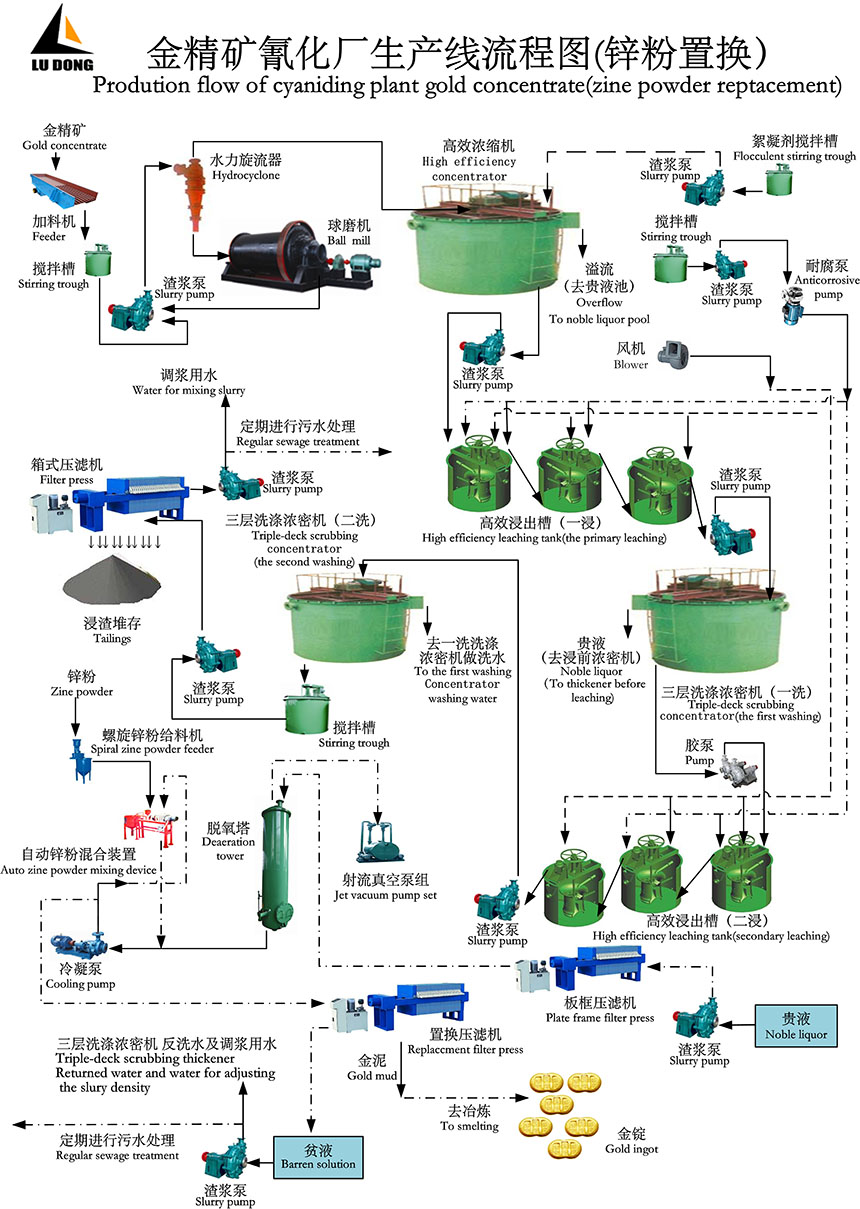

Gold concentrate cyanidation process

Page view :

Gold concentrate cyanidation process

Affiliated category :

Applicable equipment :

Feeder, ball mill, high-efficiency concentrator, high-efficiency leaching tank, three-layer scrubbing thickener, box filter press, spiral zinc powder feeder, slurry pump

Application areas :

Treatment of flotation gold concentrate or cyanide plant of mixed mercury and gravity tailings; treatment of argillaceous oxidized ores, gold extraction plant with all-slime stirring cyanidation.

重量 :

0.00

Advisory

Introduction

Flow chart