LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1 Powered by:300.cn

ABOUT US

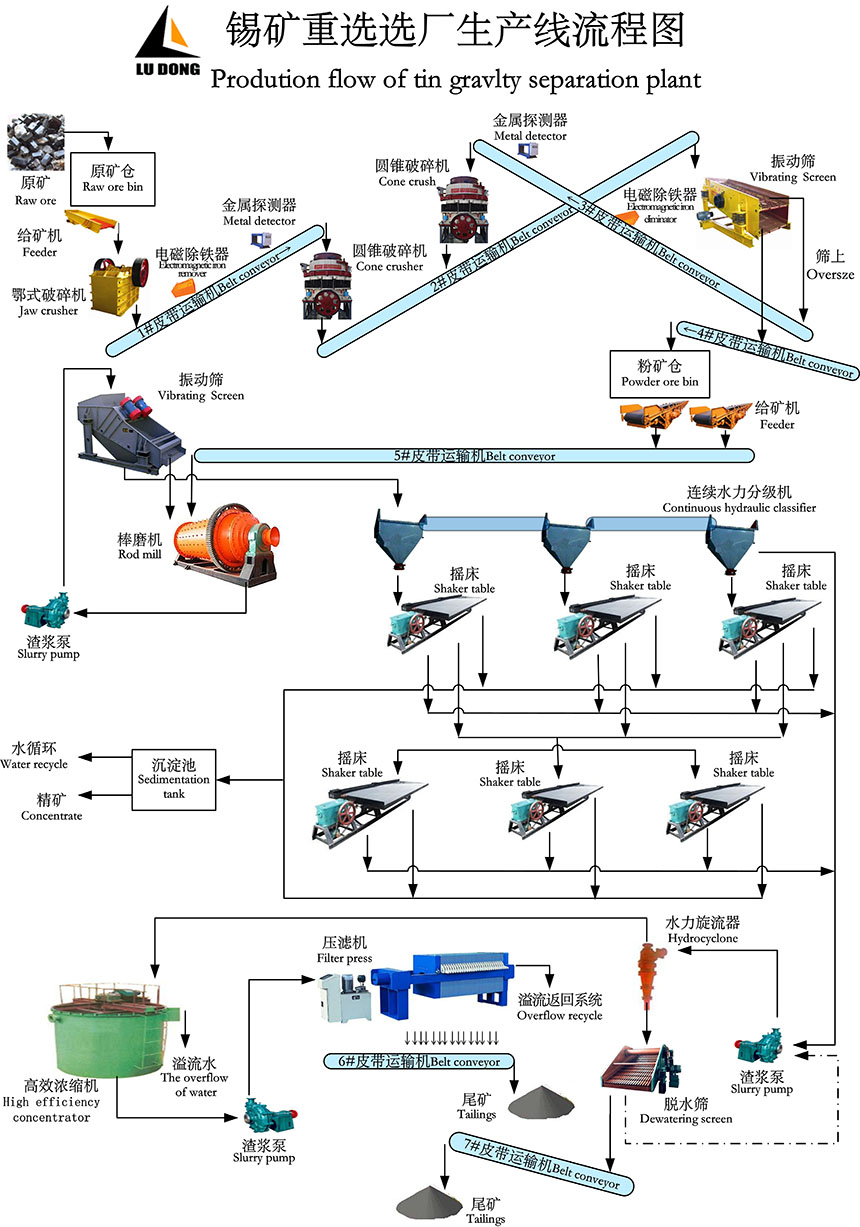

Tin mine re-election

Page view :

Tin mine re-election

Affiliated category :

Applicable equipment :

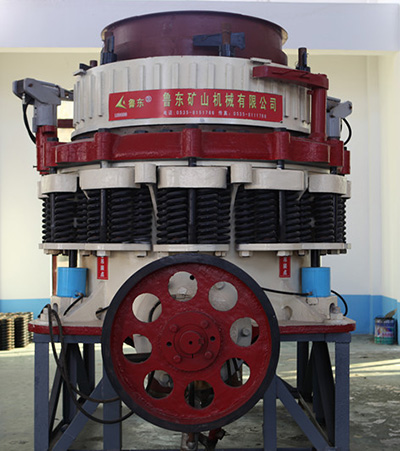

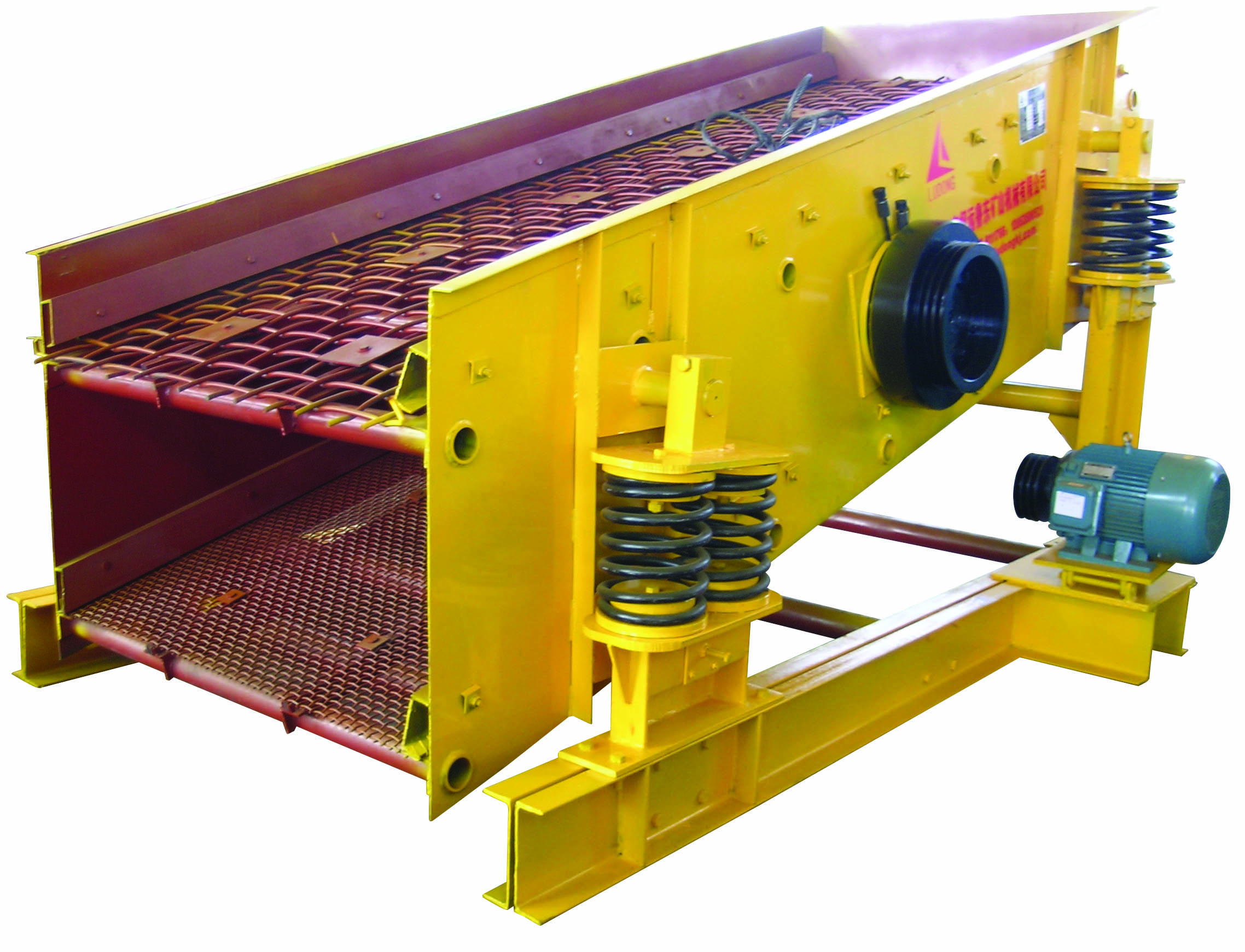

Feeding machine, jaw crusher, cone crusher, vibrating screen, belt conveyor, ball mill, shaker, plate filter press, high efficiency thickener, dewatering screen, slurry pump, hydrocyclone, slurry pump

Application areas :

The re-election method is a traditional method for treating tungsten, tin, gold ore, especially for processing gold and sand. It is also commonly used in the treatment of sand mines containing rare metals (lanthanum, cerium, titanium, zirconium, etc.).

重量 :

0.00

Advisory

Introduction

Flow chart