Preliminary test - test process

Grain size test

Through the particle size test, the content of different grades in the tailings is obtained. Combined with the previous cases, we can make a rough judgment on the choice of subsequent processes.

Dynamic Settlement Test

The speed of sedimentation of the whole tail mortar and the effect of sedimentation directly affect the supply of the whole tail mortar after concentration before the stirring device, which in turn affects the normal operation of the entire filling system. Therefore, we need to screen the selection of flocculants and test the appropriate dosage.

Rheology

The rheological parameter is the basis for the calculation of the resistance along the pipeline and is a key factor in the system design. The apparent viscosity and shear stress at different shear rates (0-100s-1) were measured by rheometer, and the relationship between the resistance loss along the horizontal pipeline and the rheological parameters was obtained.

Slump test

Paste slump refers to the plasticizing performance and pumpability of the paste. The influencing factors include concentration, lime-sand ratio, sand ratio, cement type, aggregate condition, time and temperature. Here we mainly pay attention to it. The effect of changes in paste concentration is determined by experimentation.

Strength test of different lime sand ratio filling block

The filling body not only has good workability, but its strength is also a key factor to ensure the success of the process. Therefore, we also need to test the variation of the strength of different lime sand pastes under different age conditions to determine the full tailings filling. The ratio of the paste.

Test Results

After all the test work is completed, the test process is summarized and summarized, and Xinhai will give a detailed "feasibility test report". At the end of the "Feasibility Test Report", high quality process parameters will be given.

Process Design

The full tail sand cementing filling system is mainly composed of four parts: dehydration system, agitation system, pipeline transportation system and automatic detection and adjustment system.

Processing equipment

|

|

|

|

|

Disc Feeder

|

Circular vibrating screen

|

Stirring tank

|

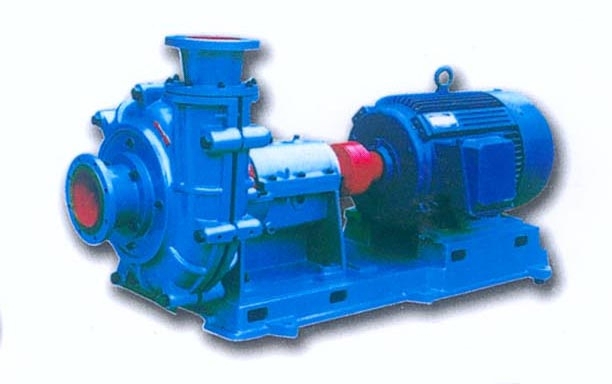

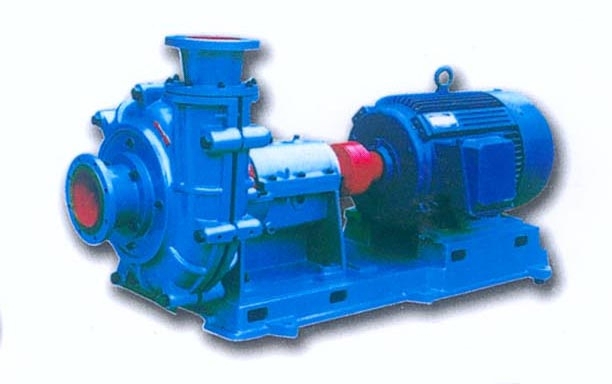

Slurry pump

|

|

|

|

|

|

Raft conveyor

|

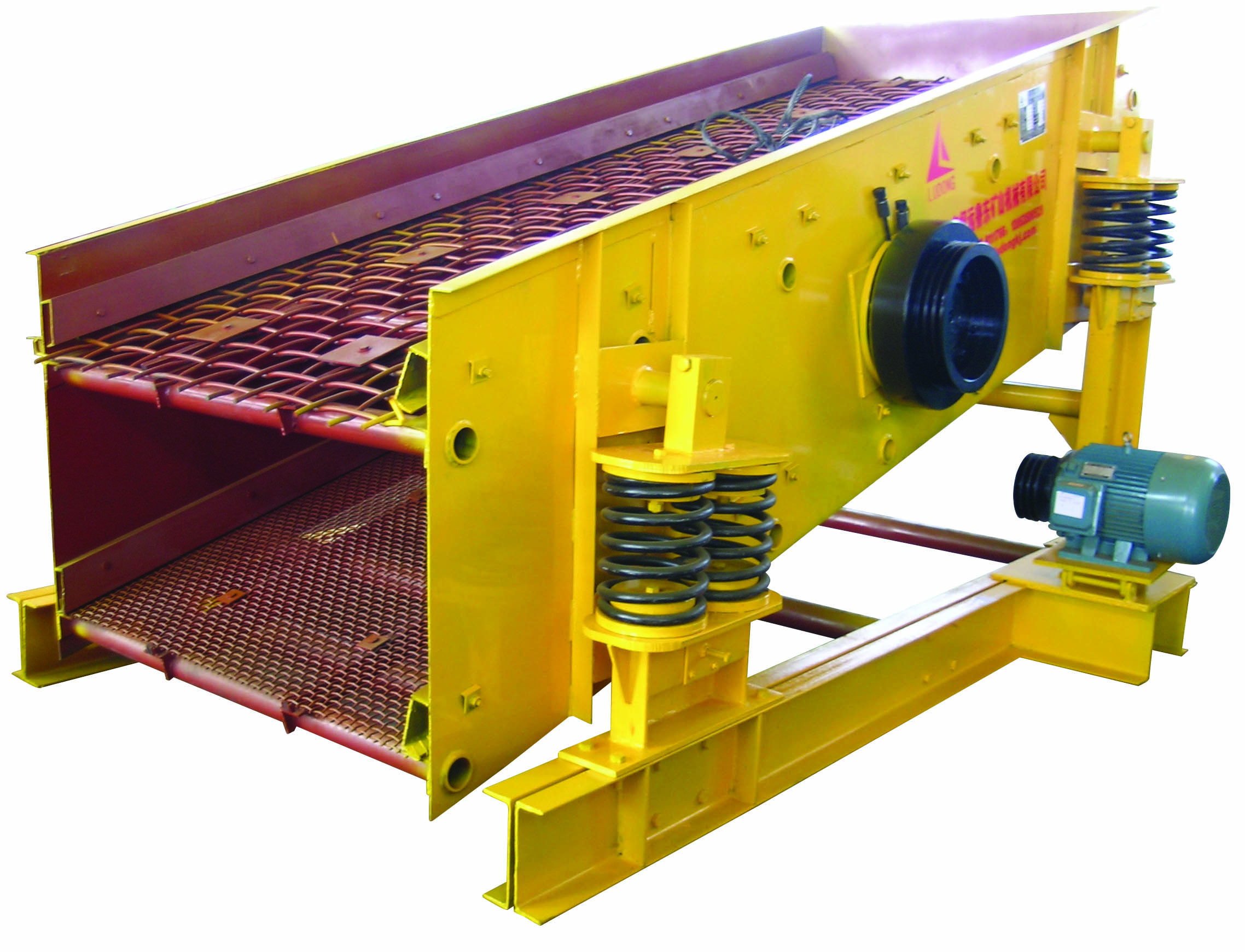

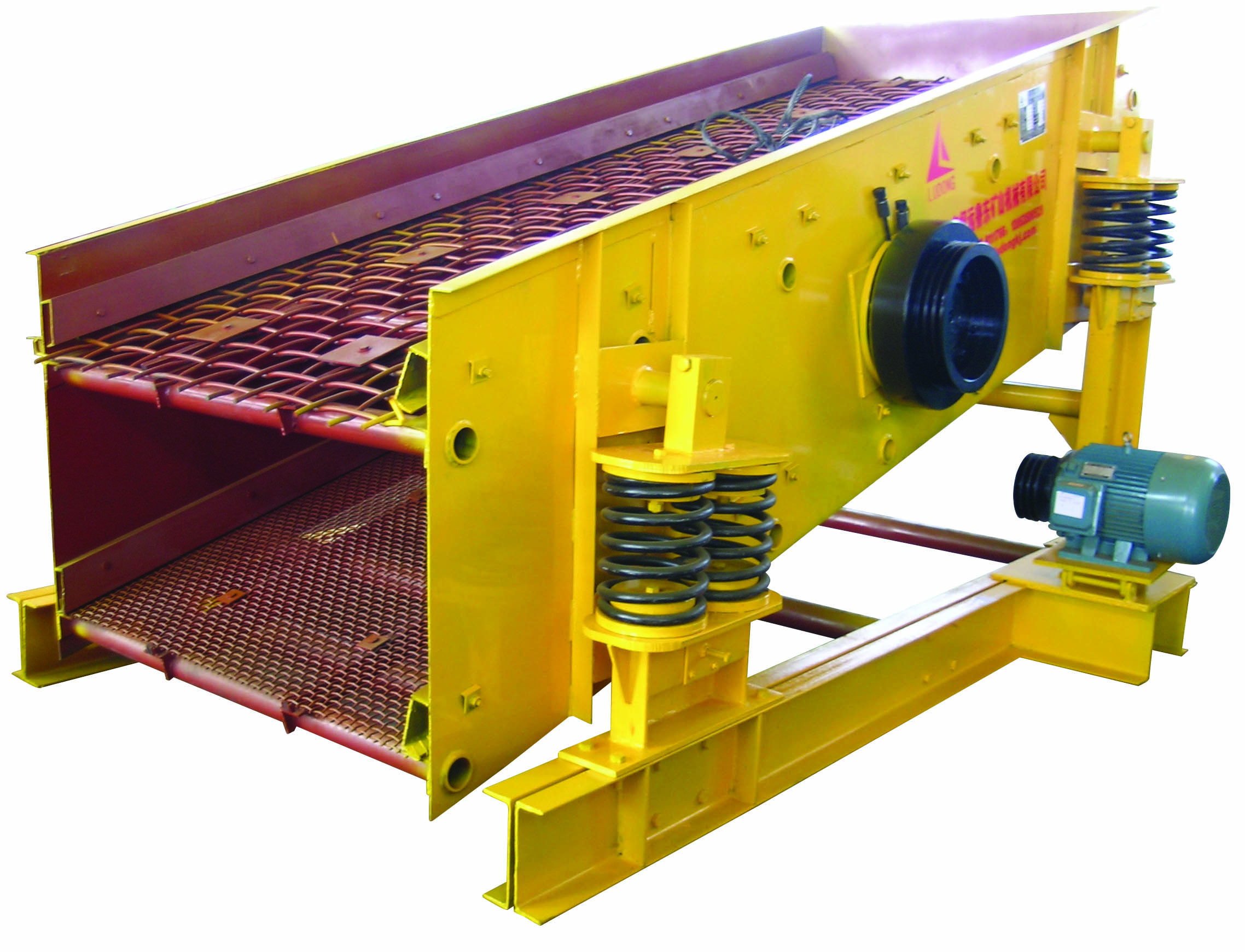

Self-centering vibrating screen

|

|

|